When planning to implement one of these systems in a facility, it’s not just about the scan room itself, but also the surroundings

Why is CT machine site planning important? It can save you a huge amount of trouble in the long run. Before you close in on that low-priced CT machine, think about space and all other requirements for your device’s site. Room configurations and preparation for site inspections require careful planning which can ultimately result in delays and extra costs if not properly set-up. To avoid this, a carefully designed CT site plan from a qualified professional specifying floor plans, equipment placement, plumbing, power requirements, shielding, and other safety measures should be used for all CT machine locations. (Keep in mind, the site planning information below is primarily for reference. Local and state requirements; site conditions; and personal preferences may also have a major impact on your final layout).

Computed Tomography (CT) machines are typically located in the ER, or a radiology suite. Sometimes they can also be found near catheterization (cath) labs and cardiology suites. When planning to implement one of these systems in a facility, it’s not just about the scan room itself, but also the surroundings. It is necessary to consider uncontrolled areas above and below the facility (especially PET/CT) as well as those on the same level.

Proper planning should be done by a qualified expert that has knowledge of both the clinical operation of an imaging facility and radiation protection design methods for CT scanners. Below, we’ve laid out considerations for a CT machine site plan checklist.

Shielding Considerations

Ceilings and/or floors with occupied areas above or below CT machine scanning rooms will most likely require shielding to reduce radiation levels. Uncontrolled areas with high occupancy should be located as far from the CT exam room as possible. If uncontrolled areas are located either above or below the PET uptake and imaging rooms, the spacing between floors may need additional shielding. Moreover, floors need to be able to support the additional weight associated with added shielding.

Ceilings for exam rooms are recommended to be at least 8 feet high. Typically, it is presumed that the patient is about 1 meter above the floor; and the dose rate is calculated at 0.5 meters above the floor (for rooms on top) and at 1.7 meters above the floor (for rooms below the exam room). Additional shielding is recommended for the nursing stations, the control room, and even vertical barriers.

The patient and the CT machine itself are considered “sources of radiation” to personnel and the public. Technicians that work directly with the patients are prone to being exposed to the most doses that can stem from patient injections, patient positioning, and unavoidable exposure during imaging. Dose levels in controlled areas are subject to ALARA (As Low As Reasonably Achievable) considerations with the maximum limits said to be 50 mSv (millisieverts – a radiation measurement unit) per year.

What can be used for shielding? Portable lead shields can be used effectively to shield patients in uptake rooms. Other shielding considerations also include walls generally requiring 0.5 to 1.0 inch lead, doors needing 0.25 to 0.5 inches lead; and viewing windows should generally be leaded glass or acrylic.

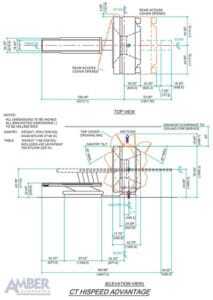

Gantry

Another important part of CT machine site planning is the gantry, the ring the patient is placed in. It can be cooled with chilled water derived from a closed loop connection from either an onsite chilled water supply or the heat exchanger. Chilled water supply must be available onsite in order to supply the heat exchanger that is located inside the gantry. If the facility will not supply chilled water, a heat exchanger cabinet is needed. The heat exchanger cabinet is then cooled with an outdoor cooling unit. As for an air-cooled gantry – this type of gantry has integrated cooling fans for air intake and air exhaust. In this instance, room air is used as cooling air, but requires thorough speculation (i.e., room size, thermal insulation, etc.) to ensure the required temperature range of air needed for the system will be properly maintained.

Get Started

Request Pricing Today!

We’re here to help! Simply fill out the form to tell us a bit about your project. We’ll contact you to set up a conversation so we can discuss how we can best meet your needs. Thank you for considering us!

Great support & services

Save time and energy

Peace of mind

Risk reduction

Climate Control

The CT exam room is recommended to remain anywhere from 64-75 degrees Fahrenheit (18-24 degrees Celsius). The rest of the CT suite can be set as low as 59 degrees to 75 degrees (15-24 degrees Celsius). It is absolutely critical that the climate be maintained at all times, even non-operating hours such as weekends, holidays, and overnight. Heat output in one section of the facility should not change the humidity and temperature in other areas. If this is a cause for concern, the exam room should be individually controlled to meet the temperature requirements.

Power Supply

CT machine site planning and construction for a CT imaging center or mobile CT sites need to be performed in compliance with all applicable local and national electric codes (NEC) and regulations. Power requirements such as supply configuration, line voltage, branch power, and circuit breakers will vary based on factors such system requirements and power consumption (whether it is standard water/water heat exchanger or air cooled system, or has an optional water/air split cooling system). Do keep in mind that the exam room should contain at least one emergency power off button.

Conclusion

All in all, it’s best to make sure you:

- Consult your provider about your site requirements.

- Check with your state’s specific requirements.

- Document the site during construction as it progresses.

- Schedule the date of construction completion.

- Finally, schedule the delivery of the CT device.

If you have questions or difficulty with your CT project planning, please do not hesitate to contact me. I’m here to help you find the CT that best fits your budget and needs. Our range includes, 4 slice ct machines, 8 slice CT machines, 16 slice ct machines, 32 slice ct machines, and much more.

For over 25 years, we’ve offered warranties and financing options tailored to the medical industry on all radiology equipment. Buying used CT machines can save you up to 60% compared to new ones, and you will never have to sacrifice quality, performance, or familiar platforms. For more information on CT Scanners, download our CT Scanner Buyer’s Guide.

Take a look at our wide range of inventory and find a CT Scanner for sale that suits your needs and requirements.